Glass bottle makers offer a wide range of designs in the glassmaking industry, with many products used frequently in modern kitchens. As the demand for oven glassware has risen, the glass industry has expanded to cater to various applications.

Over time, the uses of glass have evolved, and different types of glass, such as tempered glass, have been in use for decades. Tempered glass was one of the earliest types invented and commercialized, while borosilicate glass gained popularity for its durability and thermal resistance.

Both tempered and borosilicate glass have unique properties that make them suitable for different applications. But what exactly is tempered glass? Is borosilicate glass toxic? In this article, we’ll explore the differences between borosilicate and tempered glass, their manufacturing processes, and applications. Keep reading to learn more!

What is Borosilicate Glass?

Borosilicate glass is a specialized type of glass that contains boron trioxide, which gives it a low coefficient of thermal expansion. This means that borosilicate glass can withstand sudden temperature changes without shattering, making it the preferred material for high-end restaurants, laboratories, and vineyards.

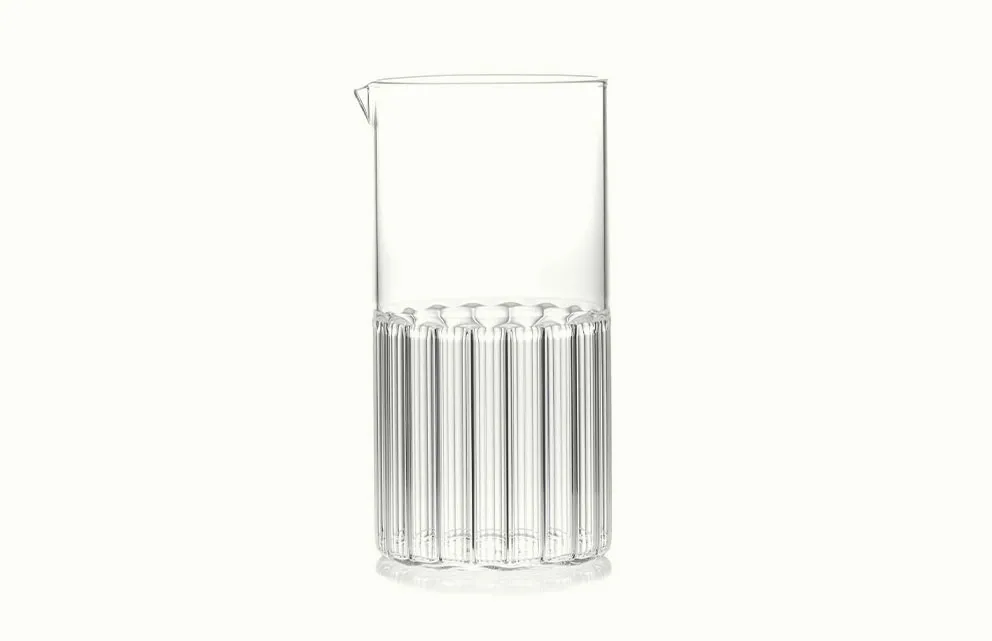

Many people are unaware that not all glass is created equal. Borosilicate glass, like the high-quality glassware produced by Roen Glass, stands out for its exceptional durability and thermal resistance.

Borosilicate glass contains approximately 15% boron trioxide, which alters the glass’s structure and makes it resistant to thermal shock. This chemical composition reduces the risk of unwanted elements leaking into the glass, making it ideal for storing hazardous materials and ensuring safety in various applications.

How is Borosilicate Glass Made?

Borosilicate glass is produced by melting a combination of materials, including:

- Silica sand

- Boric oxide

- Potassium oxide

- Zinc oxide

- Small amounts of calcium oxide and aluminum oxide

Due to its high transition temperature of up to 560°F, the melting process requires significantly higher temperatures than regular glass production.

Once melted, borosilicate glass can be processed into tubes, molded, or drawn into various shapes and sizes depending on the intended application.

Is Borosilicate Glass Safe?

Borosilicate glass is renowned for its safety and durability, making it an excellent choice for diverse applications. Its high resistance to thermal shock means it can endure extreme temperature changes without breaking, which is crucial for both laboratory and culinary settings.

Additionally, borosilicate glass is non-reactive, ensuring that it does not leach harmful chemicals into food or liquids. This makes it a safe option for food storage, laboratory experiments, and the containment of hazardous materials.

Applications of Borosilicate Glass

1. Laboratory Glassware

Borosilicate glass is extensively used in scientific settings due to its chemical and thermal resistance. It is commonly used for lab beakers, flasks, and test tubes.

2. Kitchen Experiments and Cookware

Because of its superior heat resistance, borosilicate glass is used for cookware, baking dishes, and glass cooking pots. Measuring cups made from this material maintain accurate readings even under high temperatures.

3. Optical Instruments

Borosilicate glass is ideal for producing slides and lenses used in microscopes, telescopes, and other optical devices.

4. Lighting Equipment

Borosilicate glass is widely used in high-intensity discharge (HID) lamps and studio flashlights due to its heat resistance.

5. Aircraft External Lenses

Borosilicate glass is used for aircraft exterior lighting due to its excellent optical properties and resistance to temperature variations.

What is Tempered Glass?

Tempered glass, also known as toughened glass, is a type of safety glass that undergoes heat or chemical treatment to increase its strength. Tempered glass is commonly used in structural applications such as balustrades, shower doors, and automotive windows.

During the tempering process, annealed glass is heated to approximately 188°C and rapidly cooled by blasting air on both sides. This results in the formation of compression stresses on the glass surface, while the core maintains tensile strength.

Tempered glass is significantly stronger than regular glass and is designed to shatter into small, blunt fragments rather than sharp shards, minimizing the risk of injury.

How is Tempered Glass Made?

Tempered glass is manufactured by heating ordinary annealed glass to 670°C in a toughening furnace, followed by rapid cooling. The glass surface becomes molten during this process and is cooled using jets of cold air produced by industrial coolants.

The cooling process determines the physical properties of the glass, making it more resistant to impact and thermal stress.

Applications of Tempered Glass

1. Architectural and Interior Design

Tempered glass is widely used for frameless glass doors, wall partitions, and glass entryways. It is also used in glass splashbacks and bathroom surfaces where high humidity and temperature fluctuations are common.

2. Automotive Industry

Tempered glass is commonly used in car windows, windshields, and other vehicle components where safety is paramount.

3. Consumer Electronics

Tempered glass is used in mobile phone screen protectors and tablet covers due to its scratch resistance and durability.

4. Household Applications

Shower doors, refrigerator shelves, and diving masks are all examples of applications where tempered glass is preferred due to its strength and safety features.

Key Differences Between Borosilicate and Tempered Glass

1. Thermal Resistance

Borosilicate glass has superior thermal shock resistance, allowing it to withstand extreme temperatures. Tempered glass, although heat-resistant, is not as effective as borosilicate glass in handling sudden temperature changes.

2. Manufacturing Process

- Borosilicate Glass: Produced through chemical processes that involve the inclusion of boron trioxide.

- Tempered Glass: Manufactured by heating and rapidly cooling annealed glass.

3. Durability and Strength

Tempered glass is stronger and more resistant to physical impact, making it ideal for structural applications. Borosilicate glass, however, excels in resisting chemical corrosion and extreme heat.

4. Safety Features

Tempered glass breaks into small, blunt pieces, reducing the risk of injury. Borosilicate glass maintains its integrity under high stress but may fracture into sharp pieces if broken.

Conclusion

Both borosilicate and tempered glass have unique properties that make them suitable for different applications. While borosilicate glass is ideal for high-heat applications and laboratory use, tempered glass is preferred for structural and safety-critical applications.

Roen Glass offers high-quality glass solutions that meet the highest standards. Our expertise in glass manufacturing ensures that we deliver products that exceed industry expectations. Contact us today to request a quote and experience the excellence that our clients trust!